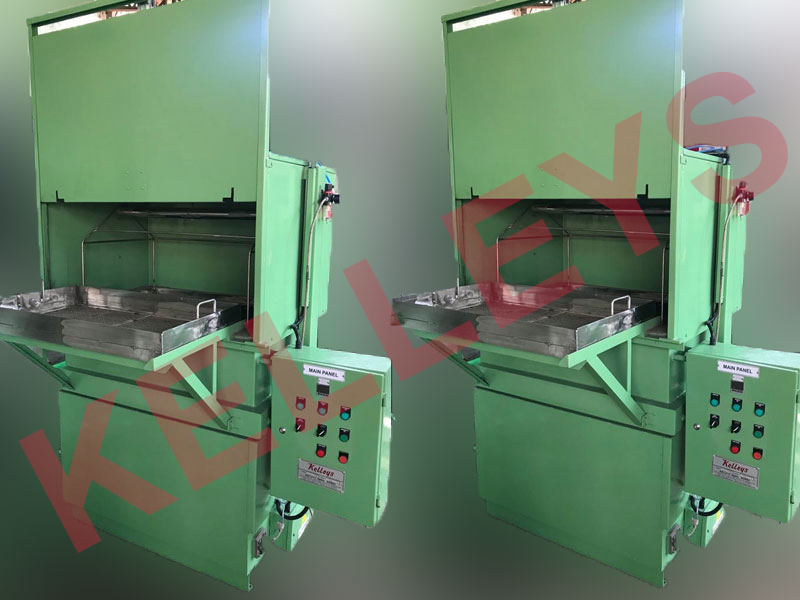

Kelleys Trichloroethylene Degreasing is a simplest and the most efficient method of removing oil and grease from the metal articles before surface treatment, finishing processes such as Electroplating, Phosphating, Anodizing, Industrial linings, Heat treatment during overhaul and during Maintanence and repairs.

Depending upon the size and the nature of articles, the degreasing process can be selected. Kelleys has supplied Batch Type as well as Continuous Type Degreasers. The process starts when the oily article is suspended in vapours, the solvent condenses on it. The oil is dissolved and falls back into the sump. The action continues till the article that is being cleaned reaches the temperature of solvent vapour. The vapour will then penetrate into the deepest recesses of the articles and clean them in matter of minutes.

In the Vapour/ Liquid Degreasing the articles are first immersed in the hot solvent , then cooled in cold liquid or atmosphere and finally degreased.

| Sno. | Effective Vapour Size |

| 01 | 600*600*400 |

| 02 | 900*600*400 |

| 03 | 1200*600*400 |